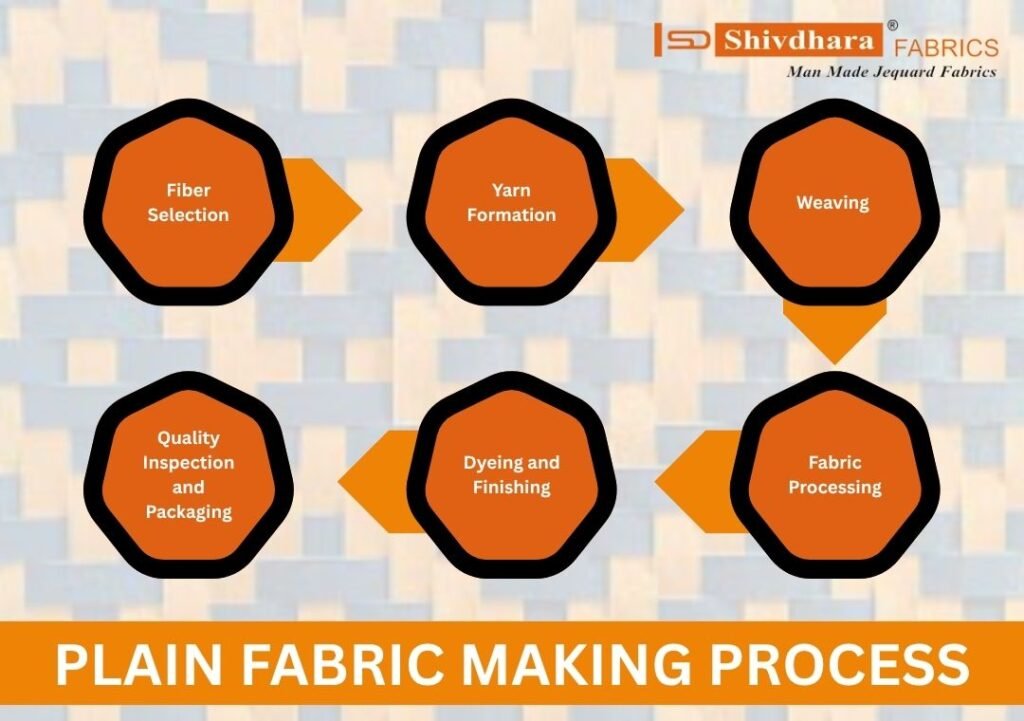

Introduction: Understanding the Plain Fabric Making Process

In the textile world, plain fabric forms the foundation of countless designs and garments. Whether it’s used in apparel, upholstery, or home décor, plain fabrics are prized for their versatility, durability, and simplicity. But have you ever wondered how plain fabric is actually made?

In this blog, we’ll take you through the Plain Fabric Making Process, step by step from raw material selection to final finishing. We’ll also highlight how Shivdhara, one of the top Plain Fabric Manufacturers in Surat, combines traditional expertise with advanced technology to produce superior-quality fabrics that meet global standards.

1. Fiber Selection – The First Step in Plain Fabric Making

The journey of plain fabric begins with choosing the right fiber. This step defines the fabric’s texture, strength, and appearance.

Types of Fibers Used:

- Natural fibers – Cotton, linen, silk, and wool.

- Synthetic fibers – Polyester, nylon, and viscose.

- Blended fibers – A mix of natural and synthetic fibers for enhanced durability and comfort.

Shivdhara, being a reputed Plain Fabric Manufacturer in Surat, uses only high-grade fibers that meet both domestic and export standards. Each batch of fiber is inspected for quality, strength, and uniformity before processing.

2. Yarn Formation – Spinning the Fiber into Thread

After selecting the fiber, the next step in the Plain Fabric Making Process is spinning. The raw fibers are converted into yarns using high-speed spinning machines.

Steps Involved:

- Cleaning and carding: The fibers are cleaned and aligned to remove impurities.

- Drawing: Fibers are drawn out into long, thin strands.

- Spinning: The strands are twisted to form yarns of the desired thickness.

The strength and smoothness of the yarn directly affect the quality of the fabric. Shivdhara’s advanced spinning setup ensures consistent yarn production, resulting in strong, even-textured fabrics ideal for multiple applications.

3. Weaving – The Core of the Plain Fabric Making Process

Weaving is the heart of fabric making. This is where the magic happens the yarns interlace to form a flat, plain surface that we call plain fabric.

The Weaving Technique:

- Plain fabric uses the simplest form of weaving known as the plain weave.

- In this weave, the warp (vertical yarns) and weft (horizontal yarns) cross each other alternately over one, under one creating a balanced texture.

- This results in a fabric that is smooth, durable, and suitable for dyeing or printing.

At Shivdhara, modern looms and precision weaving machines are used to maintain uniform tension and alignment. The result? High-quality plain fabric that looks elegant, feels comfortable, and lasts longer.

4. Fabric Processing – Preparing the Cloth for Finishing

Once weaving is complete, the freshly made fabric (often called “greige fabric”) undergoes several processing stages to improve its appearance and usability.

Key Processing Steps:

- Desizing: Removes the sizing materials applied during weaving.

- Scouring: Cleanses the fabric of natural oils, wax, and impurities.

- Bleaching: Whitens the fabric, preparing it for dyeing or printing.

- Mercerizing (optional): Enhances the fabric’s strength and luster.

These treatments ensure the fabric becomes soft, absorbent, and ready for the next stage finishing. Shivdhara’s processing techniques follow eco-friendly and water-efficient methods to reduce environmental impact.

5. Dyeing and Finishing – Adding the Final Touch

In this stage, the plain fabric gets its final look and feel. Depending on client requirements, the fabric may be dyed in solid colors or left natural.

Finishing Techniques Include:

- Dyeing: Adds rich and even color to the plain fabric using reactive or pigment dyes.

- Softening: Enhances the touch and drape of the fabric.

- Heat setting: Improves dimensional stability.

- Calendering: Smooths and polishes the surface for a refined appearance.

Shivdhara, a Plain Fabric Manufacturer in Surat, uses advanced finishing machinery to produce fabrics that are vibrant, smooth, and shrink-resistant ideal for fashion, home furnishing, and industrial uses.

6. Quality Inspection and Packaging – Ensuring Perfection

Before shipping, every roll of fabric undergoes strict quality control. The inspection team checks for weaving faults, color consistency, and surface uniformity. Only flawless fabric batches are approved for packing.

Shivdhara takes pride in maintaining world-class quality standards, ensuring that every customer receives fabric that exceeds expectations in both appearance and performance.

Conclusion: Excellence in Every Thread with Shivdhara

The Plain Fabric Making Process is a combination of art, science, and technology from fiber selection to final finishing. Each stage plays a crucial role in determining the fabric’s durability, texture, and beauty.

At Shivdhara, one of the most trusted Plain Fabric Manufacturers in Surat, the focus is on blending craftsmanship with innovation. With a commitment to quality and sustainability, Shivdhara delivers premium-grade plain fabrics that empower designers, retailers, and garment makers to create stunning apparel and décor.

Whether you need cotton, polyester, or blended plain fabrics, Shivdhara ensures unmatched consistency, smooth finish, and long-lasting quality making it your perfect partner in the textile journey.